Overview

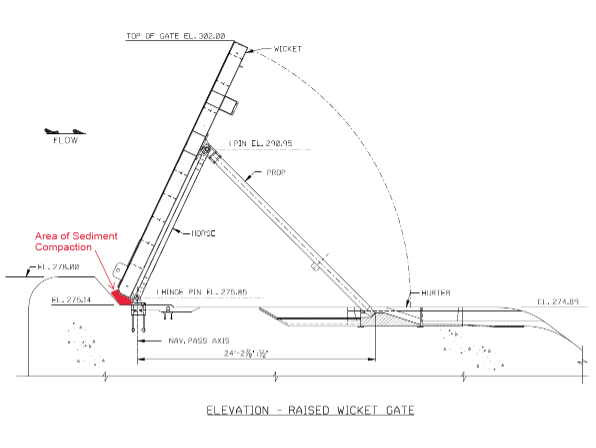

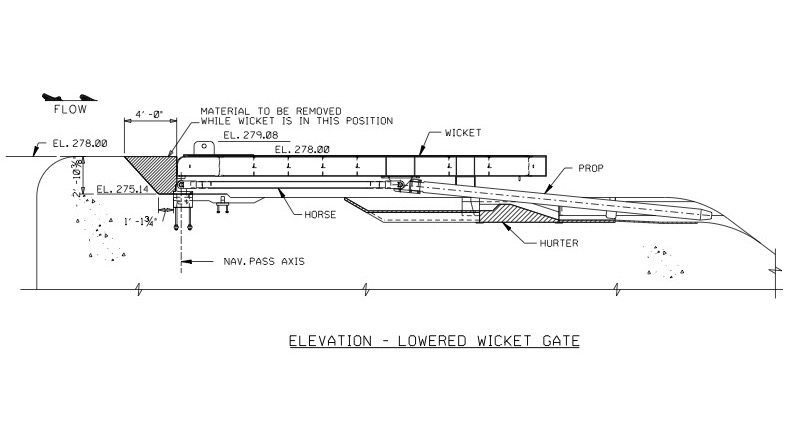

The U.S. Army Engineer Research and Development Center (ERDC)’s Coastal and Hydraulics Laboratory seeks solutions capable of clearing sediment from a wicket trench located at the Olmsted Locks and Dam in Olmsted, Illinois.

Currently the trench is being cleaned by use of divers, which is part of a costly contract that also supports maintenance of the wickets on the dam. It is expected that solutions will effectively complete trench cleaning in no more than two 12-hour shifts when the water is 30’ or less in depth.

Project Objective

The objective of this two-phased capability assessment is to identify and determine the feasibility of various wicket cleaning systems that replace the traditional use of a diver. Proposed concepts may include the use of above surface cleaning arms, dredge sleds or robotic submersible systems to remove the material trapped in the wicket trench. All potential solutions will be considered.

Background

The current process involves a towboat and crane barge used for the dive platform during the trench cleaning operation. Velocities are typically measured below 7.5 fps, but the maximum measured velocity has been 9 fps. Depth to the trench is typically 30’ or less, which doesn’t create a major limitation for the divers. Physical exertion and helmet velocity are typically the limiting factors for divers.

The wicket dam has a very short duration of time between lowered condition and raised condition. Dam is raised in response to the river flows and the goal is to raise it in one 12-hour shift. Equipment to raise the dam consists of a knuckle boom crane which resembles a custom excavator with a hook. This is mounted to a barge that is connected to the Kentucky side of the dam by winches. The barge is pushed by a small towboat along the wickets as they are raised sequentially. The crane has ability to use various attachments but attempting to clean out the trench while raising the wickets would greatly increase the time to raise the wickets. Therefore, the wicket trench is cleaned and inspected independently of the wicket lifter and prior to initiating the raising of the wickets.

Requirements

ERDC invites pre-proposals that introduce the available technologies to improve the efficiency of wicket trench cleaning on locks and dams. Proposed solutions can be an advanced idea or can build on existing technology. All potential solutions will be considered.

The wicket trench cleaning and inspection system must meet the following requirements:

- No diver to enter the trench

- Works in river velocities up to 7.5fps

- Works in depths up to 30’

- Accomplished prior to wicket raising process (in less than two 12-hour shifts)

- Removes material and allows inspection (material does not need to be brought to the surface, it can be displaced by the current downstream)

Not required, but highly desired:

- Works in river velocities up to 9fps

- Can be deployed by existing onsite equipment, towboat, cranes, etc. (requires minimal additional new support equipment)

- Control systems as simple as possible and compatible with other control systems at the lock

- Allows traffic to pass nearby while the system is deployed

- Requires two people or less to continue operation (after initial deployment)

Note: Submissions should NOT include confidential or proprietary details. Submissions may be shared with other ERDC teams if there is an apparent fit with other ERDC projects.

Expected Result

Phase I: ERDC gains an understanding of the market, assesses the applicability of new and existing systems for USACE locks on the inland waterways, and ascertains the experience and capability of the submitting parties. Down-selected parties will be considered for possible funding support in Phase II.

Phase II: ERDC may issue a solicitation to down-selected parties including a performance work statement (PWS) requesting a technical proposal and the associated cost.

Evaluation Criteria

Submissions will be evaluated based on the following criteria:

- Technical Merit – Feasibility and applicability of proposed solution

- Cost/Schedule – Preparedness and appropriateness of cost and schedule details cited

- Business Viability – Organizational capacity, years in operation, relevant specialties and capabilities

- Prototype/Demo – Technology Readiness Level (TRL) and availability of this solution for demonstration, if needed

Submissions must be formatted as prescribed in the pre-proposal template. Submissions will be evaluated by ERDC and USACE subject matter experts.

Notional Project Schedule

Proposed project milestones include:

| August 15, 2023 | Project Announced, Submissions Open |

| August 29, 2023 | Question Period Ends, FAQ Document Finalized |

| September 5, 2023 | Submissions Close |

| September 5-15, 2023 | Evaluation Period; Virtual Pitch Hosted (if needed) |

| September 18-29, 2023 | Participants Selected for Phase II Notified by ERDC |

| FY 2024 | Award Phase II Contract(s) |

*If needed; dates may vary to accommodate project team and participant availability.

How to Participate

- Submit specific details by providing a pre-proposal (download template)

- Review FAQs

- Once pre-proposal is ready to submit, complete the submission form.

Questions: Please send all technical and administrative questions using this form. Q&A will be updated periodically. It is the responsibility of the offeror to review Q&A prior to submitting a pre-proposal.